Popular

Not sure which filter membrane to use? Well, this page is for you! It’s easy to overlook membrane compatibility when picking out filters for sample filtration. Good membrane-sample compatibility supports efficient filtration and minimizes resistance, while poor compatibility might result in backpressure, ineffective filtration, or even chemical attack of your membrane, leading to contamination of your filtrate.

How to Choose the Best Filter?

With just 5 questions!

- What are you filtering? Determine:

- Size and nature of the particles or molecules to be removed

- Chemical composition

- Temperature

- Viscosity

2. What pore size or nominal molecular weight rating (NMWL) is required to achieve separation?

3. Will this be a sterilizing filtration?

4. How quickly do you need to filter? I.e., what is the volume and available processing time?

5. Will you use pressure-driven or vacuum-driven filtration?

Types of Filtration Processes & Procedures

There are many filters with different filtration media composition, each designed for particular applications. Filter selection depends on several factors, including:

- Size of the particles or molecules to be excluded or included

- Chemical composition of the sample

- Compatibility of the filtration media with sample or solution

- Sample viscosity

Filters can be made from different types of materials, such as paper, cloth, cotton-wool, asbestos, slag- or glass-wool, unglazed earthenware, sand, or other porous material. Membrane filters are usually made from synthetic polymers (e.g. hydrophilized PTFE, PVDF, nylon, PES).

Different forces can be applied to drive the filtration process. Filtration can be driven by simple gravity using a filter and a funnel, manually as in syringe filtration, or by centrifugal force. In vacuum-driven filtration, a vacuum pump is used to rapidly draw the fluid through a filter.

Our wide range of membrane filtration are autoclavable and compatible with membrane discs!

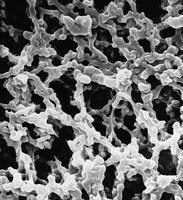

MIXED CELLULOSE ESTERS

Material: MCE (mixed cellulose esters)

Features: General/Buffer filtration and particle monitoring

Applications: Air monitoring and contamination analysis for fuels and hydraulic fluids. Clarification and sterilization of fluids/buffers.

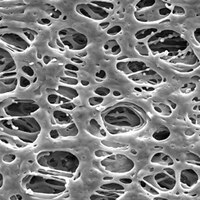

NYLON MEMBRANE

Membrane: Nylon Membrane

Features: Low organic extractables and broad chemical compatibility

Applications: Particle analysis, large particle filtration, prefiltration of solvents. Compatible with a broad range of solvents.

POLYVINYLIDENE FLUORIDE

Membrane: PVDF (Polyvinylidene Flouride)

Features: Low Protein Binding

Applications: Particulate removal. Compatible with aqueous solutions and some organic solvents.

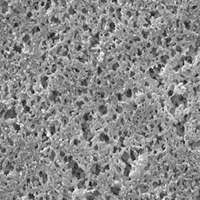

POLYETHERSULFONE

Material: PES (polyethersulfone)

Features: High throughput and low protein binding

Applications: Clarification and sterilization of fluids, mainly aqueous. Ideal for hard-to-filter solutions.

CELLULOSE ACETATE

Membrane: CA (Cellulose Acetate)

Features: Low Protein Binding

Applications: Filtration of protein and enzyme solutions, tissue culture media and serums, biological fluids, and similar applications where maximum recovery of protein is critical.

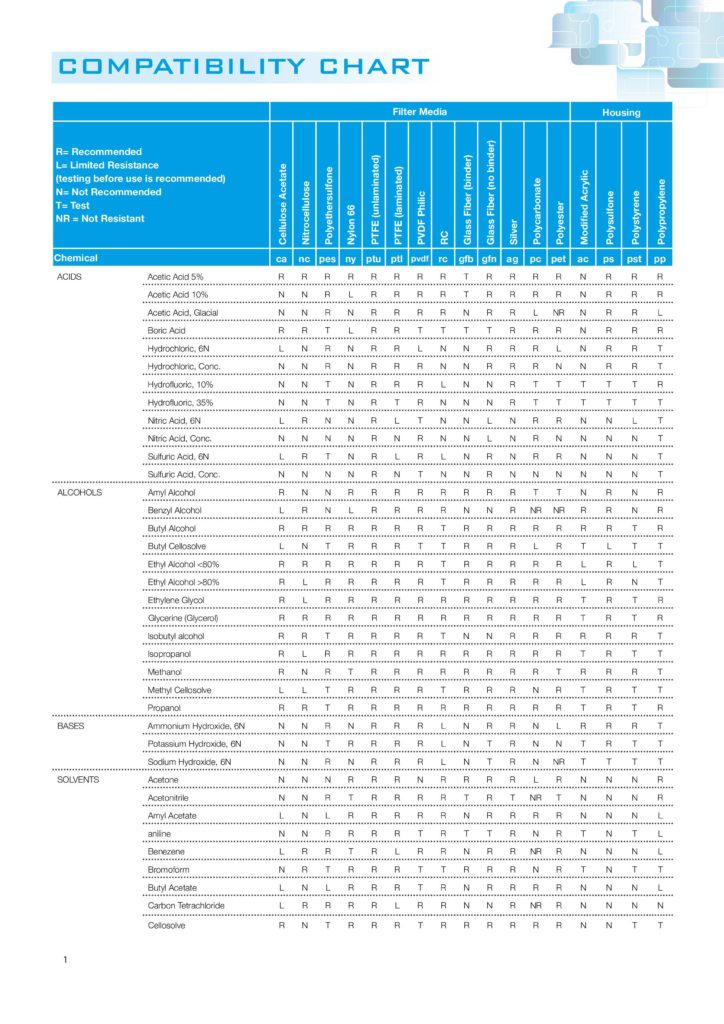

Selection Guide

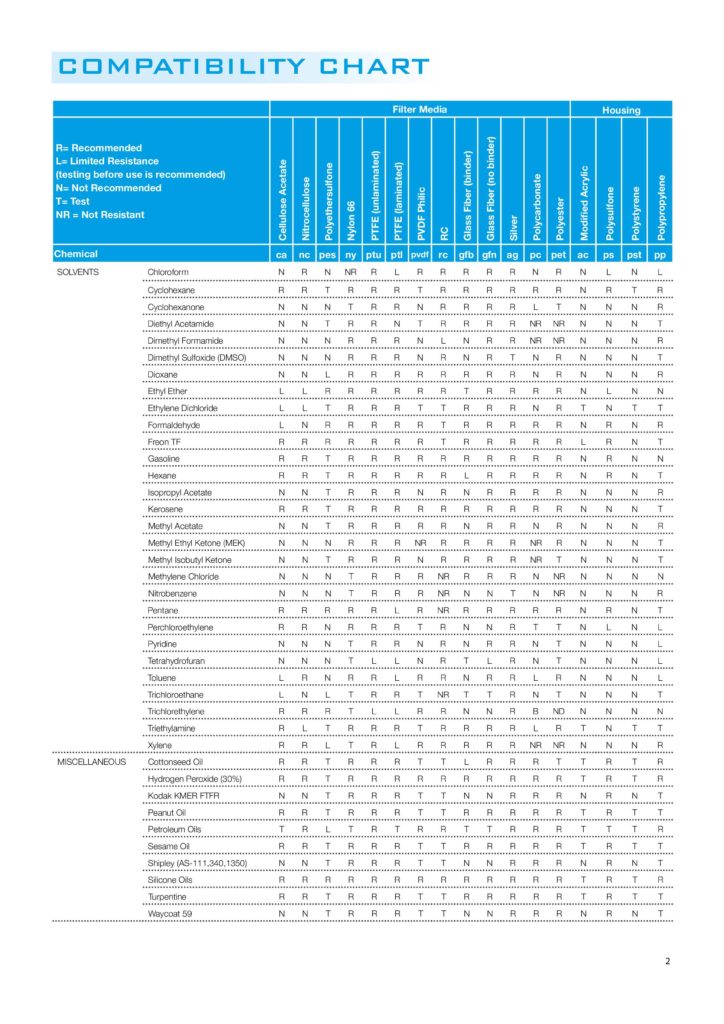

Check out the Chemical Compatibility here!

Need Help Selecting the Right Filtration Membrane? Don’t hesitate! Contact us for advice today!

Written by labstoreonline

Latest News

Best offers

100% Safe

Secure Shopping

24x7 Support

Online 24 Hours

Best Offers

Grab Now

After Sales

Service Provided

Ask Quotation

for FREE